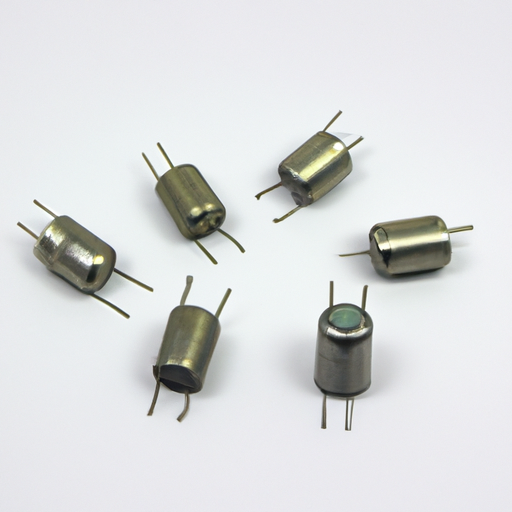

Ceramic capacitors are a type of electronic component that is widely used in various electronic devices and circuits. They are essential for storing and releasing electrical energy in a controlled manner, making them crucial for the proper functioning of many electronic systems. In this article, we will explore the different types of ceramic capacitors, their applications, advantages, and disadvantages.

There are several different types of ceramic capacitors, each with its own unique characteristics and applications. The most common types include:

1. Multilayer ceramic capacitors (MLCCs): These are the most widely used type of ceramic capacitors. They consist of multiple layers of ceramic material stacked on top of each other, with alternating layers of metal electrodes. This design allows for a high capacitance in a small package size, making MLCCs ideal for compact electronic devices.

2. Ceramic disc capacitors: These capacitors have a disc-shaped ceramic body with metal electrodes on either side. They are typically used in high-voltage applications, such as power supplies and motor drives.

3. Ceramic chip capacitors: These capacitors are similar to MLCCs but are designed in a chip form factor, making them suitable for surface-mount applications. They are commonly used in consumer electronics, telecommunications equipment, and automotive systems.

4. High-voltage ceramic capacitors: These capacitors are designed to withstand high voltages, making them suitable for applications that require high insulation resistance and breakdown voltage. They are commonly used in power distribution systems, medical equipment, and industrial machinery.

Ceramic capacitors have several advantages that make them popular in the electronics industry. One of the main advantages is their high capacitance density, which allows for a large capacitance in a small package size. This makes them ideal for compact electronic devices where space is limited. Additionally, ceramic capacitors have a low equivalent series resistance (ESR) and equivalent series inductance (ESL), which results in high efficiency and low power losses.

Another advantage of ceramic capacitors is their excellent stability over a wide range of temperatures and frequencies. They have a low temperature coefficient, meaning that their capacitance value remains relatively constant over a wide temperature range. This makes them suitable for applications that require precise and stable capacitance values, such as in precision instrumentation and communication systems.

Despite their many advantages, ceramic capacitors also have some limitations. One of the main drawbacks is their limited voltage rating compared to other types of capacitors, such as electrolytic capacitors. This can be a limiting factor in high-voltage applications where a higher voltage rating is required. Additionally, ceramic capacitors are more prone to microphonic effects, which can cause noise and interference in sensitive electronic circuits.

In conclusion, ceramic capacitors are an essential component in modern electronic devices and circuits. They offer high capacitance density, low ESR and ESL, excellent stability, and a wide range of applications. While they have some limitations, such as limited voltage ratings and susceptibility to microphonic effects, their advantages far outweigh their drawbacks. As technology continues to advance, ceramic capacitors will continue to play a crucial role in the development of innovative electronic systems.

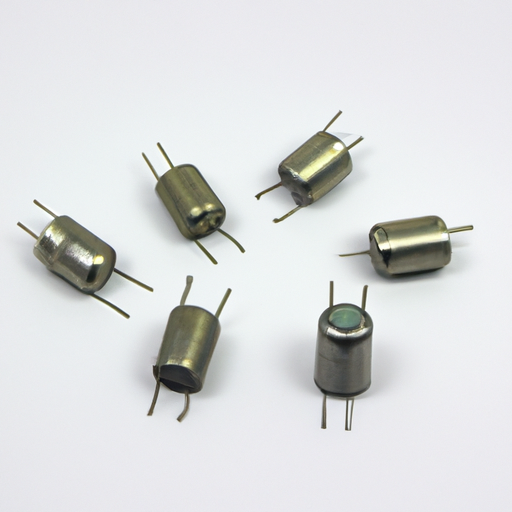

Ceramic capacitors are a type of electronic component that is widely used in various electronic devices and circuits. They are essential for storing and releasing electrical energy in a controlled manner, making them crucial for the proper functioning of many electronic systems. In this article, we will explore the different types of ceramic capacitors, their applications, advantages, and disadvantages.

There are several different types of ceramic capacitors, each with its own unique characteristics and applications. The most common types include:

1. Multilayer ceramic capacitors (MLCCs): These are the most widely used type of ceramic capacitors. They consist of multiple layers of ceramic material stacked on top of each other, with alternating layers of metal electrodes. This design allows for a high capacitance in a small package size, making MLCCs ideal for compact electronic devices.

2. Ceramic disc capacitors: These capacitors have a disc-shaped ceramic body with metal electrodes on either side. They are typically used in high-voltage applications, such as power supplies and motor drives.

3. Ceramic chip capacitors: These capacitors are similar to MLCCs but are designed in a chip form factor, making them suitable for surface-mount applications. They are commonly used in consumer electronics, telecommunications equipment, and automotive systems.

4. High-voltage ceramic capacitors: These capacitors are designed to withstand high voltages, making them suitable for applications that require high insulation resistance and breakdown voltage. They are commonly used in power distribution systems, medical equipment, and industrial machinery.

Ceramic capacitors have several advantages that make them popular in the electronics industry. One of the main advantages is their high capacitance density, which allows for a large capacitance in a small package size. This makes them ideal for compact electronic devices where space is limited. Additionally, ceramic capacitors have a low equivalent series resistance (ESR) and equivalent series inductance (ESL), which results in high efficiency and low power losses.

Another advantage of ceramic capacitors is their excellent stability over a wide range of temperatures and frequencies. They have a low temperature coefficient, meaning that their capacitance value remains relatively constant over a wide temperature range. This makes them suitable for applications that require precise and stable capacitance values, such as in precision instrumentation and communication systems.

Despite their many advantages, ceramic capacitors also have some limitations. One of the main drawbacks is their limited voltage rating compared to other types of capacitors, such as electrolytic capacitors. This can be a limiting factor in high-voltage applications where a higher voltage rating is required. Additionally, ceramic capacitors are more prone to microphonic effects, which can cause noise and interference in sensitive electronic circuits.

In conclusion, ceramic capacitors are an essential component in modern electronic devices and circuits. They offer high capacitance density, low ESR and ESL, excellent stability, and a wide range of applications. While they have some limitations, such as limited voltage ratings and susceptibility to microphonic effects, their advantages far outweigh their drawbacks. As technology continues to advance, ceramic capacitors will continue to play a crucial role in the development of innovative electronic systems.