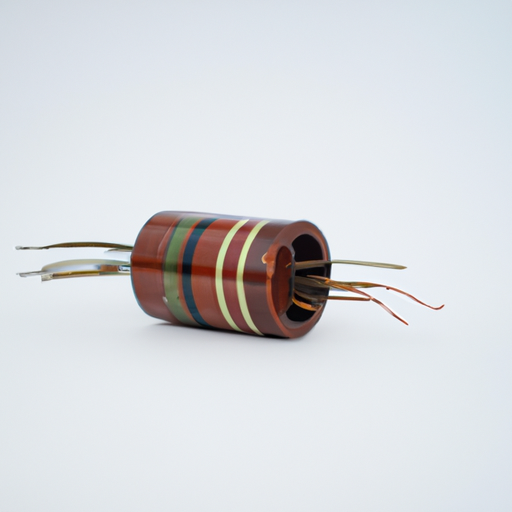

Film capacitors are a type of capacitor that is widely used in various electronic devices and applications. They are known for their high reliability, long lifespan, and excellent performance characteristics. In this article, we will explore the different types of film capacitors, their construction, working principle, advantages, and applications.

There are several types of film capacitors, including metallized film capacitors, foil film capacitors, and hybrid film capacitors. Metallized film capacitors have a thin metal layer deposited on the film, while foil film capacitors have a separate metal foil as the electrode. Hybrid film capacitors combine the advantages of both metallized and foil film capacitors.

The working principle of film capacitors is based on the storage of electrical energy in the electric field between the two metal layers. When a voltage is applied across the electrodes, an electric field is created in the dielectric material, which stores the energy. The capacitance of a film capacitor is determined by the area of the electrodes, the distance between them, and the dielectric constant of the film material.

Film capacitors have several advantages over other types of capacitors. They have a high insulation resistance, which makes them suitable for high voltage applications. They also have a low equivalent series resistance (ESR) and equivalent series inductance (ESL), which results in low power losses and high efficiency. Film capacitors are also known for their high reliability and long lifespan, with some capacitors lasting for decades without any degradation in performance.

Film capacitors are used in a wide range of applications, including power supplies, motor drives, lighting systems, audio equipment, and telecommunications devices. They are commonly used in filter circuits, timing circuits, and coupling circuits, where high stability and low losses are required. Film capacitors are also used in high-frequency applications, where their low ESR and ESL make them ideal for filtering out noise and interference.

In conclusion, film capacitors are a versatile and reliable type of capacitor that is widely used in various electronic devices and applications. They offer high performance, long lifespan, and excellent stability, making them a popular choice for engineers and designers. With their low losses, high efficiency, and high insulation resistance, film capacitors are an essential component in modern electronics.

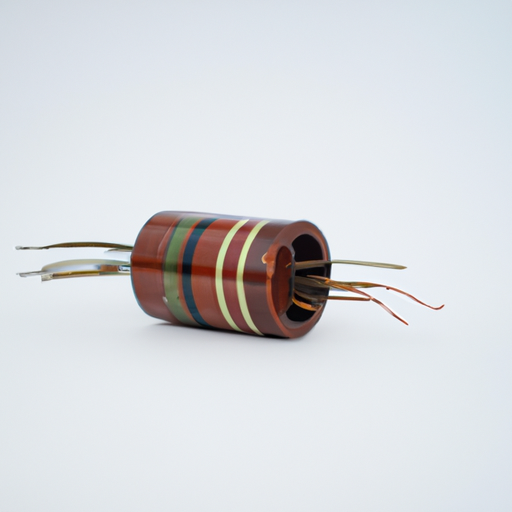

Film capacitors are a type of capacitor that is widely used in various electronic devices and applications. They are known for their high reliability, long lifespan, and excellent performance characteristics. In this article, we will explore the different types of film capacitors, their construction, working principle, advantages, and applications.

There are several types of film capacitors, including metallized film capacitors, foil film capacitors, and hybrid film capacitors. Metallized film capacitors have a thin metal layer deposited on the film, while foil film capacitors have a separate metal foil as the electrode. Hybrid film capacitors combine the advantages of both metallized and foil film capacitors.

The working principle of film capacitors is based on the storage of electrical energy in the electric field between the two metal layers. When a voltage is applied across the electrodes, an electric field is created in the dielectric material, which stores the energy. The capacitance of a film capacitor is determined by the area of the electrodes, the distance between them, and the dielectric constant of the film material.

Film capacitors have several advantages over other types of capacitors. They have a high insulation resistance, which makes them suitable for high voltage applications. They also have a low equivalent series resistance (ESR) and equivalent series inductance (ESL), which results in low power losses and high efficiency. Film capacitors are also known for their high reliability and long lifespan, with some capacitors lasting for decades without any degradation in performance.

Film capacitors are used in a wide range of applications, including power supplies, motor drives, lighting systems, audio equipment, and telecommunications devices. They are commonly used in filter circuits, timing circuits, and coupling circuits, where high stability and low losses are required. Film capacitors are also used in high-frequency applications, where their low ESR and ESL make them ideal for filtering out noise and interference.

In conclusion, film capacitors are a versatile and reliable type of capacitor that is widely used in various electronic devices and applications. They offer high performance, long lifespan, and excellent stability, making them a popular choice for engineers and designers. With their low losses, high efficiency, and high insulation resistance, film capacitors are an essential component in modern electronics.